Add-on option to our

Add-on option to

our

plant, producing

high quality

gasoline

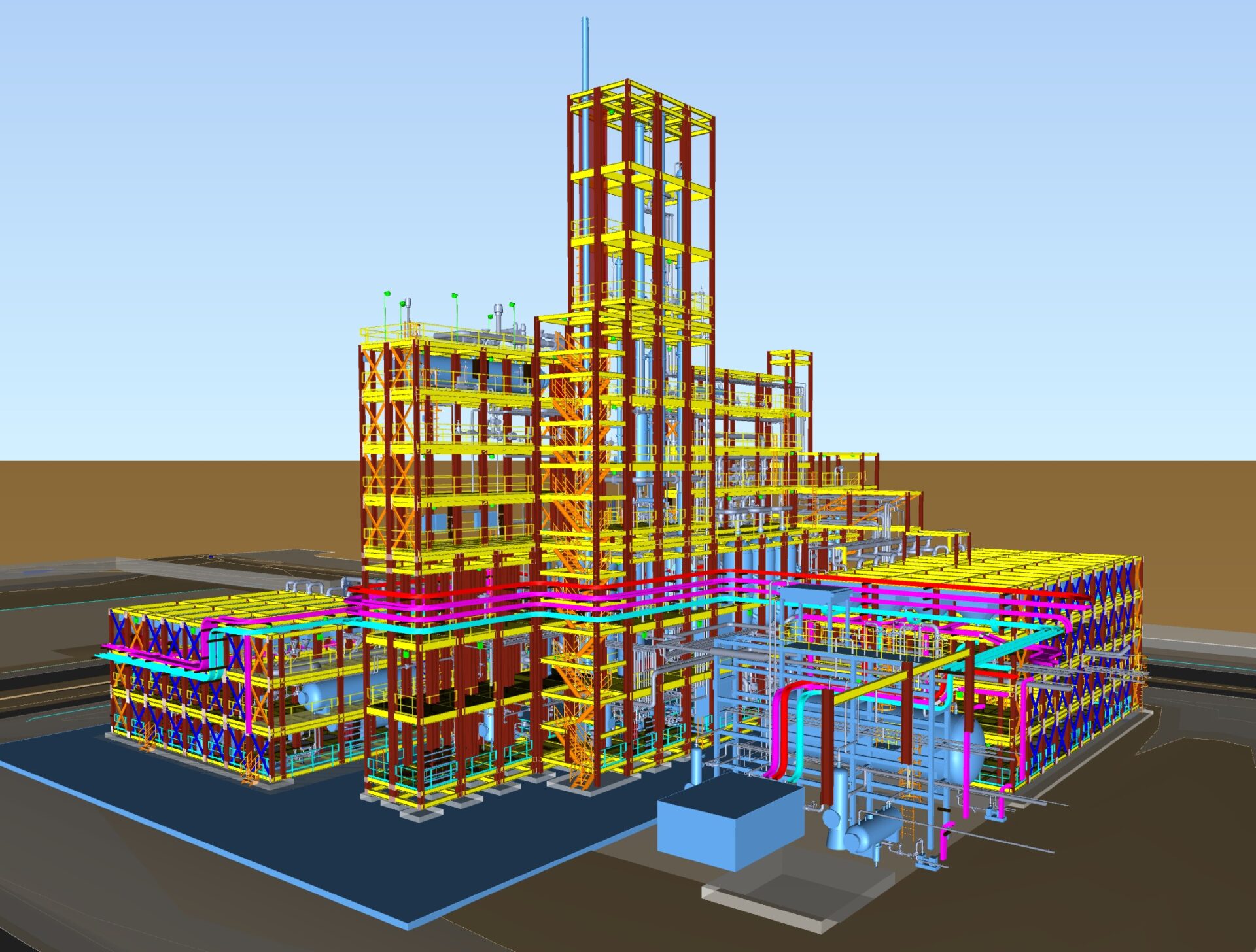

Convert flared gas, stranded gas or any other syngas feedstocks into a liquid motor fuel that can be used locally or can be transported by truck to nearby markets with Gasoline-To-Go®. Our Gasoline-To-Go® plant incorporates well-proven methanol-to-gasoline technology with Modular Plant Solutions’ small-scale modularization technology, reducing field construction risk and making the plant moveable if needed. This add-on package to an MeOH-To-Go® plant produces 88 octane gasoline ((R+M)/2) plus LPG instead of methanol, or production of gasoline and LPG in combination with methanol. With feedstock flexibility, users can also produce low carbon gasoline with Gasoline-To-Go®.

How it works

The Gasoline-To-Go® plant combined with MeOH-To-Go® includes all chemical processing equipment modules required to produce high octane, low sulfur gasoline. The plant includes heat exchanger modules, reactor modules, distillation modules, compressor and pump modules, as well as storage tanks and truck loading facilities for gasoline and LPG. The result is a high quality, low sulfur, low benzene motor fuel that meets typical gasoline specifications and only requires the addition of an additive package. With an additive package, the fuel can be used directly in gasoline fueled vehicles, with no other treatment or purification. The LPG produced by Gasoline-To-Go® is a mixture of propane and butane, which can be burned as a fuel or sold into the mixed LPG market.